Ever since T8 LED tubes were introduced, they have become nothing but an efficient addition for the indoors. These lights are eligible for illuminating both residential and commercial spaces. It doesn’t matter if you are looking for lights to light up a home, office, hospital, factory, or any other commercial location, the lights are simply eligible for enhancing visibility with their apt illumination.

As a matter of fact, there is a concept of bypassing ballast that is applicable in these T8 LED tubes. This means that the LED tubes can work just as fine, even if the ballast fixture is not plugged into them. For people who don’t know what ballast is, it is a fixture that is usually found in conventional tube lights. This fixture helped the lights to work by directing current flow.

However, modern T8 LED tubes can work without ballasts. Some LED tubes can even light up the space with the ballast bypass procedure. 8ft, 6ft, and 4ft LED ballast bypass bulbs are some common examples of that. In addition, these types of lights are also called direct wire LED tubes.

This is an upgrade that is usually preferred for retrofitting LED lamps. For instance, you can perform a 4ft LED ballast bypass bulb in your existing fluorescent tubes with a pre-installed ballast. The retrofitting alternative allows you to remove the ballast fixture, or you can even prefer the direct wire method.

Moving on, ballast is an external attachment used in fluorescent tubes. One can easily replace it and convert the fluorescent tube to LED. Like the fluorescent used ballast, you are supposed to replace that fixture with a driver that will divert the current, allowing the light to glow. The reason for doing this is simply to allow the T8 LED tubes to modulate energy with an apt current flow.

Furthermore, for upgrading the fluorescent tubes with, let’s say 4ft LED ballast bypass bulbs, you are required to remove the ballast fixture. This will end up making the light direct wire T8 LED tubes. If you are planning to perform this procedure, you need to follow the steps mentioned below:

Remove ballast from the old fluorescent fixture.

Direct wire the drivers.

Connect T8 LED tubes to the external drivers.

Switch on the connection.

Although to save you from the chaotic bypass procedure, manufacturers are producing upgraded versions of T8 LED tubes. These tubes are already capable of working without a ballast. The connection has an already fixed driver. So, they do not require you to attach a driver connection. You just need to make sure that the LEDs are eligible for the ballast bypass.

Additional information on LED tubes

Moving forward, new 8ft, 6ft, and 4ft LED ballast bypass bulbs are available with integrated or in-built drivers. This helps in making the lights eligible for direct wiring. With that, you can connect new LED lights by removing old ballast lights completely. Plus, you are not even required to add a driver separately to the power source.

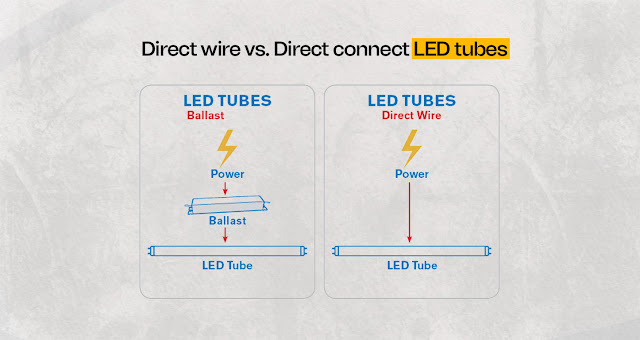

Whether you talk about direct wire LED tubes or LED tubes using ballast, the existence of ballast is witnessed. Direct-wired T8 LED tubes are designed in such a manner that they can be connected to the power source directly. On the other hand, the T8 LED tubes with ballasts are designed to work with a ballast attachment, but you can upgrade it to a bypass one.

Direct wire vs. Direct connect LED tubes

Setting up direct wire LED tubes is quite tricky in the beginning, as you are supposed to remove the ballast fixture. However, this will benefit you in the future as the fixture will not trouble you with issues related to ballast failure. Also, there is no additional cost involved in bypassing the ballast from T8 LED tubes.

Direct connect 4ft LED ballast bypass bulbs

Lights that work with a ballast fixture are known as directly connected tubes. They can be easily installed, and you are not required to remove the ballast fixture. Instead, just remove old fluorescent tubes and replace them with LEDs. But these are not ideal for the long run because, sooner or later, the ballast fails to work appropriately. The lifespan of direct connect LED lights is quite less than LED lights. Also, there is an additional cost involved in bypassing the ballast.

Comments

Post a Comment